Sigmacure

Sigmacure

The most versatile PUCB binder system in the market HAI's Sigmacure products owes its position as the leading core production process due to its versatility, efficiency, and cost-effectiveness. Sigmacure offers a wide selection of part ones and part twos resins to meet all production requirements and specifications.

Proven results

- The highest levels of casting quality

- Highly complex castings, such as thin wall thickness

- Ideal for highly automated production

- Can be used with many alloys

To learn more, view our Sigmacure Technical Data Sheets.

System Features

- High productivity, fast cycle times

- Good processability and good bench life of the sand mixture even when a suboptimal substrate is used

- Excellent dimensional accuracy

- Moisture-resistant, even under difficult ambient conditions

- Flexible/customizable system for special requirements

- Suitable with a large variety of equipment

- High process safety

- Lowest cost use

- Low-risk system / higher degree of safety

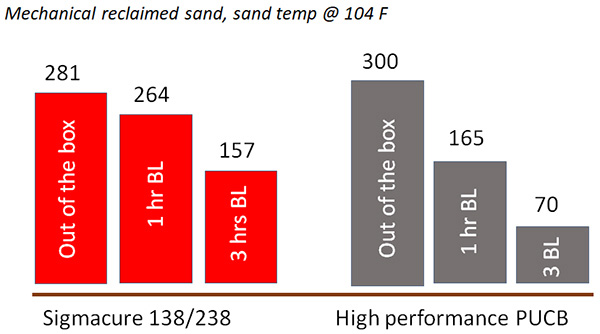

Sigmacure 138/238

Engineered to deliver the best bench life properties, especially when adverse ambient conditions exist, and hot sand is prevalent.

- Excellent performance when hot sand, hot ambient conditions, as well as relative high humidity are an issue

- Engineered mainly for Fe applications

- Best bench life performance

- Good hot strength

Sigmacure 127/217

- High-performance PUCB binder

- High out-of-the-box tensile strengths

- Excellent choice for tight dimensional tolerance castings

- Helps to minimize shrinkage defects associated with PUCB systems

- The first option for high-value, high-production aluminum applications

- An excellent option for the SPM process

- Low condensables

- Reliable bench life performance

- Performs with both ferrous and non ferrous alloys

Sigmacure 135 P1

Sigmacure 235 P2

Sigmacure 210MOD P2

- Increase core-making productivity

- Fastest cycle-to-cycle

- Fast curing speed

- Outstanding wipe-off properties

- Reduce downtime at core-making

- Avoid dumping unnecessary sand from hoppers

- Exceptional release properties

SC135/210MOD (better)

SC135/235 (best)

- Improve hot strength for Fe applications (*SC 210MOD)

- High out-of-the-box strengths (*When Hybrid systems are used)

- Excellent bench life compare to other standard systems

Technical Assistance

HAI can help you optimize your operation, improve your performance, and help you choose components to meet all your core-making needs. HAI will help you choose the right Part 1 to Part 2 ratios for your operation. Contact us today and let one of our experienced employees help you find the best binder to achieve your goals.

.png?width=268&height=81&name=logo-new2%20(1).png)