HA International News

WE ARE HA-INTERNATIONAL

Serving as the Largest Supplier of Products for Core and Mold Production

to the North American metal casting industry. Created as a joint venture in 2001, today we are part of the global HA Group. Our parent company supplies the global metal casting industry through a highly integrated network of subsidiary and affiliated companies.

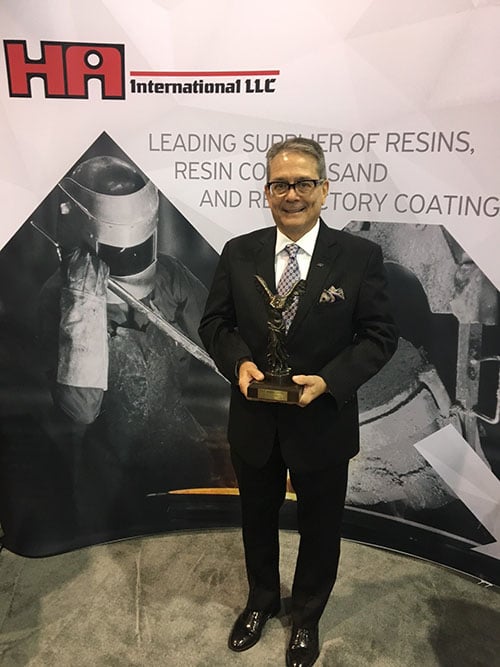

HA INTERNATIONAL ANNOUNCES GORDON MCNEILAGE AS NEW CEO

Westmont, Illinois – HA International is excited to appoint Gordon McNeilage to the position of CEO, effective January 1st, 2024. Gordon succeeds Mike Feehan, who had this to say: “Gordon joined HAI in 2023 and has led the commercial team as VP of Sales and Marketing. He comes to HAI with vast experience in the foundry industry and as an experienced professional executive, which makes him well-suited for the position. He has developed company cultures in his career that perfectly align with the HAI culture.”

Gordon has over 25 years in the industry and has run operations in South Africa, China, and the USA. He was recently the Senior Business Director at SI Group after completing roles of increasing responsibility in his 18 years with the company. Gordon began his career in the Foundry industry after completing his Metallurgical Engineering degree from the University of Witwatersrand, South Africa. He has moved through roles in Sales, Operations, Marketing, andExecutive Management.

“I am honored and excited to rejoin the HA Family and feel truly humbled to be given the opportunity as CEO to lead HAI into the future and continue the great work by Mike,” said Gordon. “Setting HAI on a growth path while fostering an amazing culture where all HAI employees can be successful both in a professional and personal capacity.”

The HA Group Presidents, Christoph Koch, and Franz Butz, expressed their “highest gratitude for Mike's achievements and best wishes for Gordon.” Mike has been the President/CEO for the last six years and with the company for over 32 years.

CastTherm® Korplete Engineered Additives

An HAI Total Solution for mold and core making applications

Silica sand is a smart choice for foundry sand because of its high refractoriness and low cost in use. Unfortunately, it's not without limitations. Korplete additives, in combination with sand, provide improved near-net shape casting surface while reducing costs in casting cleaning.

HA-International offers a portfolio of CastTherm Korplete engineered additives to help foundries move beyond most silica sand limitations to eliminate casting defects. Just a small addition of CastTherm Korplete to enhance your sand mix can:

- Reduce/eliminate surface-based defects

- Potentially reduce resin resulting in a reduction in gas-related defects

- Reduce time in the cleaning room

- Eliminate the need for coatings or a more expensive specialty sand

TYPES OF KORPLETE

HAI has the engineered additives to meet your needs head-on. Our CastTherm Korplete products include:

- CastTherm Korplete 1190 - Coarse black iron oxide sand additive formulated with magnetite (Fe3O4). Good for AM 3D applications.

- CastTherm Korplete 3217 - Inorganic sand additive that is a solution to lithium-based sand additives. Suitable for both iron and steel applications.

- CastTherm Korplete 3654 - Manufactured inorganic/organic based hybrid additive effective at reducing veining in thin-walled iron applications while maintaining low gas evolution.

- CastTherm Korplete 1217 - Additive that is effective at replacing red iron oxide (hematite), black iron oxide (magnetite), and blends of both, while seeing the benefit of improved tensile strengths.

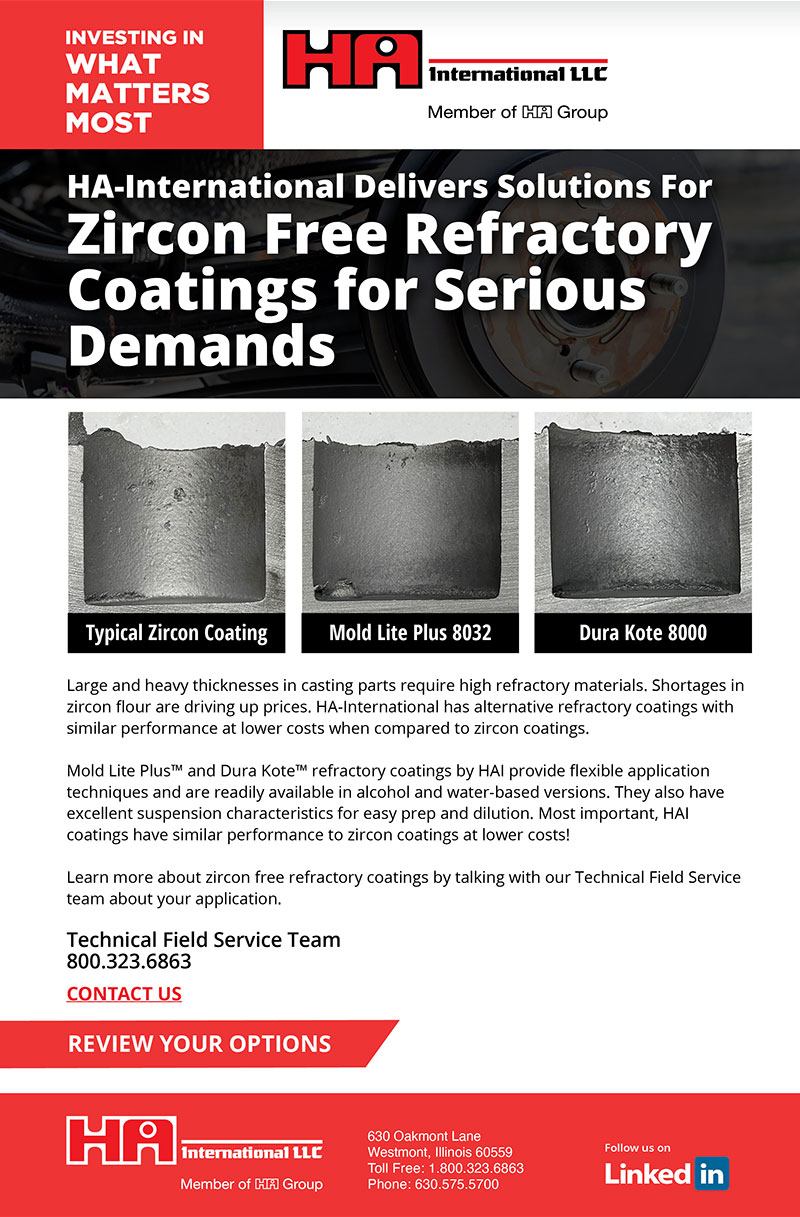

HA-International Delivers Solutions For Zircon Free Refractory Coatings for Serious Demands

Large and heavy thicknesses in casting parts require high refractory materials. Shortages in zircon flour are driving up prices. HA-International has alternative refractory coatings with similar performance at lower costs when compared to zircon coatings.

Mold Lite Plusâ„¢ and Dura Koteâ„¢ refractory coatings by HAI provide flexible application techniques and are readily available in alcohol and water-based versions. They also have excellent suspension characteristics for easy prep and dilution. Most important, HAI coatings have similar performance to zircon coatings at lower costs!

Learn more about zircon free refractory coatings by talking with our Technical Field Service team about your application.

Technical Field Service Team

800.323.6863

Aluminum Fluxes 101 - Basics of Furnace Cleaning, Dross Handling and Wall Cleaning

Casting defects, energy usage, metal recovery, ergonomics, and labor are cost variables addressed by properly identifying and applying fluxes for the aluminum casting operation. Proper selection and application are especially important to realize the benefits that flux can provide.

Defects stemming from the use of dirty metal are plentiful. Metallic aluminum is very reactive with atmospheric oxygen, and a thin passivation layer of aluminum oxide (4 nm thickness) forms on any exposed aluminum surface in a matter of hundreds of picoseconds to form aluminum oxide (Al2O3). Hydrogen forms whenever molten aluminum meets water vapor, and easily dissolves into the melt. The gas tends to come out of the solution and forms bubbles when the melt solidifies. The detrimental effects arising from the presence of an excess of dissolved hydrogen in aluminum are numerous. Aluminum oxide and hydrogen gas H2 are the two most common defects found in aluminum castings. Magnesium formation is also common in aluminum melting due to reaction with the alloy or with the refractory which typically contains magnesium and oxidizes rapidly forming magnesium aluminate (spinel), which visually forms black speck inclusions in the metal surface. Aluminum fluxes will address all three potential inclusions from the process of melting to final molten metal preparation. This article will cover two of the seven fluxes listed below*, drossing and wall cleaning fluxes, and some of the key savings.

HA-International Awarded EcoVadis Silver Medal

Introducing Bioset opTa

HA-International's new, second generation of the Bioset T family of products is here! The Bioset opTa80 and Bioset opTa85 resin package will continue to move both HAI and the foundry market towards a greener future.

The Bioset opTa80/85 package was designed to have similar smoke and odor reductions as compared to the original Bioset T system with a great economic value.

Bioset opTa80/85 is a revolutionary reformulation of our current formula, and still provides similar tensile and hot strength compared to Bioset T8000/T8500.

The benefits of Bioset opTa80/85

- Lower odor, smoke, VOC and HAP emissions at pouring, cooling, and shakeout (compared to standard PUNB)

- Superior tensile strength

- Low free formaldehyde

- High hot strength for ferrous and non-ferrous applications

- Comparable to the original BiosetTM T system

Thank you for stopping by our booth

Conversations with customers and partners made CastExpo 2022 a great experience and a huge success. We hope you feel the same.

HA-International was a featured speaker on three talks, gave several in-booth presentations, and met with dozens of people one on one. We have a lot of prepared information and solutions to help you with end-to-end metal casting solutions.

Contact us if you didn't get a chance to see our speakers, the in-booth presentations, or have a conversation with one of us in our booth. We can't wait to see how we can help with your foundry process.

Honored By Ecovadis for our environmental efforts

HA Group and HA-International are proud to share some news with you. We've been awarded a silver medal for corporate responsibility and business sustainability from EcoVadis, the world's most trusted provider of business sustainability ratings, intelligence and collaborative performance improvement tools for global supply chains.

We're passionate about lessening the impact our products have on the environment without sacrificing the quality of our castings. This silver rating places us in the top 25% of companies that were evaluated.

We are truly humbled to be recognized for our efforts to create a smaller footprint on our planet as we continue to provide you, our valued customers, with a wide range of industry-leading foundry binders, resin coated sand, and refractory coatings with reduced EHS impacts.

Next-Generation Chromite Sand

Chromite sand formulated in prepared sand mixtures for the core room or in green-sand molding applications will be influenced by the screen distribution. The CastTherm family of chromite sand is a naturally occurring, sub-angular chromite aggregate mined in the heart of the Bushveld Complex in South Africa, in partnership with Rand York Minerals. These next-generation chromite sands have become popular for various alloys because of the available screen distributions and the average grain-fineness number.

In molding applications where high thermal conductivity, heat resistance, dimensional stability, and casting surface finish are critical, CastTherm Sand is the recommended solution. These chromite sand distributions support the production of castings with various alloy applications because they act as a "chill" (also known as thermal durability.) The resulting screen distribution of the chromite sand influences many foundry applications, including the casting surface appearance, binder level requirements, and overall performance.

Where Innovation and Value Meets Application

CastTherm® CR Chromite Improves molding and casting properties

HA-International, in partnership with Rand York, is proud to introduce CastTherm Chromite to the North American foundry market.

Over the last decade, casting production has seen a dramatic increase in demand for intricate designs and shapes to meet everchanging customer needs. We've also seen increased issues with availability and escalating prices for ceramics and zircon materials.

The availability of multiple screen distribution CastTherm CR (or Chromite) sands offers a broader solution to meet this need head-on.

The Recommended Solution

In molding applications where high thermal conductivity, heat resistance, dimensional stability, and casting surface finish are critical, CastTherm Chromite is the recommended solution. These chromite sand distributions support the production of castings with various alloy applications because they create optimal surface finish under demanding conditions. The resulting screen distribution of the chromite sand influences many foundry applications, including the casting surface appearance, binder level requirements, and overall performance.

CastTherm CR foundry grade chromite is used for its:

- Highest chilling properties of specialty sands

- Excellent thermal conductivity

- High sintering point

- Low thermal expansion

- Lowers cost-in use (reduced defects, cleaning room)

- Range of available GFN distributions

Types of CastTherm

The CastTherm CR 45 product is the conventional material used by steel and gray iron foundries for mold and core production. CastTherm CR 60 and CastTherm CR 80 because of their finer GFN have a more comprehensive range of foundry and alloy applications than CastTherm CR 45 and offer a solution to other specialty sands. Chromite sand's chilling tendency at the mold metal interface, higher heat-transfer consideration, and refractory characteristics of the CastTherm CR 60 and 80 chromite sand can create an improved surface finish.

HA International Is Proud To Present: A Domestic Alternative to High Cost Furan Resins

ENVIROSET 138 PNB

Enviroset 138 PNB is a high performance acid cure phenolic resin that is a proven suitable binder for large ferrous castings and a fitting replacement to traditional furan resins.

- Excellent hot strength suitable for large castings

- Fastest curing profile (Work Time / Strip Time) compared to other products in this segment

- High tensile strengths profile

- It can be cured using HAI current acid catalysts portfolio

Additional features and benefits:

- Non-reportable free formaldehyde

- Low initial viscosity

- Low nitrogen

- Excellent reclamability

- Low odor at mixing compared to similar resins in this segment

Cutting Edge Feeding Technology for Advanced Casting Processes

The use of exothermic and insulative feeding systems - sleeves and pouring cups - have been common practice for many years. Increasingly over the last three decades, foundries have improved productivity by increasing the number of castings per mold. This economical change has resulted in more restrictive positioning of the feeding sytems on the pattern plate.

This reduction in feeder size and contact area makes it challenging to maintain feeding performance. Advancements in manufactured feeding solutions continue to be developed to meet these challenges foundries face with balancing improved processes, productivity and costs while maintaining high quality castings.

We're Celebrating 20 Years!

For 20 years, HA-International has been doing one thing with absolute focus and tenacity: proudly serving the needs of our customers. And we think that's something to celebrate!

Since Delta-HA and Borden Chemicals merged in 2001, HA-International has honored the 100+ years of global service those two companies provided. Along the way, we evolved into a trusted leader in innovative products and solutions that bring superior value to our customers.

We are excited to share our 20th anniversary with you as we continue our passion for performance, quality, consistency and customer focus. Now more than ever, we remain driven to re-invent products and services while exceeding your expectations.

Thank you for the opportunity to serve such a wonderful industry. Your hard work and determination inspire us to achieve even higher standards of excellence.

Metal Feeder Technology POWERED BY CHEMEX

HIGH PERFORMANCE FEEDER SYSTEMS

Chemex Feeder Systems are especially ideal for complex castings including intricate designs and rapid molding processes. This technology uniquely allows feeder placement in previously inaccessible locations.

The exceptional variety of Chemex feeders provides you with many options in feeding systems for your complex castings. The ultramodern method of fabrication with cold box binder systems combined with the innovative tele-feeder technique represents a major breakthrough in feeder technology.

Tele-Feeder-System

Oval contact meets thin section needs

Video

Side Insert Sleeves

No hidden hot spots with side insert feeders

Video

Modulus function in feeder geometry

Learn More

Brochure

Foundry-Skills.com Video-Wiki

Aachen, Germany, January 2021. Foundry-Skills is a new, free video wiki with thousands of foundry-specific short videos spread across more than 45 categories. From sand casting to investment casting, from hand moulding to quality assurance, from aluminium to zinc. Here trainees, students, onboarding newcomers and career changers, casting buyers, design engineers and lecturers in foundry technology will find a modern access to expert knowledge in addition to literature.

In a virtual tour through the real foundry world, you can literally look over the foundryman's shoulder as he works, see how real work processes actually run in detail, experience casting processes in direct comparison, as well as different casting materials in different applications.

Evaluating Phenolic Urethane Cold Box Environmental Advantages

The Phenolic Urethane Cold Box process (PUCB) is the most widely used, organic chemical process for coremaking in North America. Its reputation for being versatile, highly productive, and cost efficient are the reasons it remains popular today, especially for metalcasting in the automotive, mining, and agricultural supply chains.

The appreciation for PUCB systems primarily comes from these benefits: faster cycle times; applicability for ferrous and nonferrous casting; excellent performance for highly complex cores; high mechanical strength; and effective thermal characteristics.

Feeder Technology Powered by CHEMEX

Finally, a feeding material that provides a shrinkage-free casting and increases casting productivity - even on the most complex designs.

Chemex Tele-feeder Systems are especially ideal for complex castings including intricate designs and rapid molding processes. This technology uniquely allows feeder placement in previously inaccessible locations.

Significant Benefits:

- Increases productivity with higher yield and faster cleaning time

- Increases quality with reduced casting scrap and rework

- Reduces environmental footprint with reduced energy

- Decreases scrap - low fluorine content results in reduction of fluorine content in molding sand, which leads to a decrease of scrap

- Expands the locations for feeder placement

- Reduces surface defects with fluorine-free material

5 Keys to Reducing Casting Defects Through Refractory Coatings

In an industry that has been around for many centuries with a wealth of knowledge and experience, we still today find ourselves when analyzing casting defects asking, "what changed?" This is because we understand that our industry is process dependent and controlling those processes is key to success. Refractory coatings are one of the products that we utilize to produce quality castings. Although usage is small in comparison, these products are applied at the mold/metal interface which is critical when it comes to defects. Crushes, inclusions, scabs, expansion, gas, metal penetration, misruns and rough surface defects can all be affected by refractory coating practices. Therefore, how do we control this aspect of our foundry operations?

Want A Cleaner, Stronger Casting Alloy?

Start your casting process with clean, oxide and hydrogen-free molten aluminum. With HAI's Wedron Flux Metal Processing Solutions in your metal preparation process, you can:

- Produce cleaner degassed alloys

- Reduce the overall metal content of your dross

- Keep your furnace running clean and efficient

Improved casting integrity and enhanced cleanliness of your molten metal processing system means defect-free aluminum castings produced with less downtime and fewer manhours.

Wedron's environmentally friendly products and services for molten metal processing include a wide range of flexible systems that can be tailored to your individual production needs.

Phenolic Urethane Cold Box Process

If you have dealt with core / mold making in the metal casting process, then most likely at some point you have dealt with the Phenolic Urethane Cold Box process (PUCB). PUCB is the most popular binder system for coremaking and the most widely organic chemical process in North America. The main key drivers that have propelled the PUCB is its versatility, productivity, and cost of use. Industries such as the automotive, mining, and agricultural depend on PUCB for their core making process.

Phenolic Urethane No-Bake Binder (PUNB)

Bioset T8000

An exclusive HAI PUNB technology that delivers the lowest smoke and odor at molding, pouring, cooling & shakeout without compromising your bottom line

PRODUCTIVITY & QUALITY

High mechanical tensile strengths

- Maintains mold/core integrity at handling, closing, and pouring using lower binder levels

Engineered for different applications

- Ferrous and non-ferrous

- Core and mold making

- New and reclaimed sand systems

Excellent performance when reclaimed sands are used

- High reclaimability ratio

- Low cost of usage

- $US/TON of mixed sand

CC EcoFlo Resin Coated Sand

Improve your shell core making environment in hot & Humid climates!

REDUCED EMISSIONS

70% reduction in ammonia and formaldehyde emissions vs. conventional formulas

INCREASED HUMIDITY RESISTANCE

Humidity resistance is substantial vs. other environmental grades

REDUCED LUMPING

Reduced lumping means better flowability in hot and humid climates

The name is new. The reputations are legendary. HA Quimica de Mexico S.A. de C.V.

For almost three decades, foundries in Mexico have trusted HA-International and Garmi del Norte S.A. de C.V. for their commitment to making better castings.

Today, these two companies are unified under one name to serve the Mexican foundry industry, HA Quimica de Mexico S.A. de C.V.

Our new name and look reflects our singular and continued commitment to the development and distribution of innovative resins, resin coated sand, refractory coatings and metal feeding systems to produce better castings at less cost.

As a combined company, we are the most trusted name in the Mexican foundry industry as the largest supplier of products for core and mold production.

"This new joint venture with our long-standing partner GARMI represents an important step for the HA Group, and further strengthens our global foundry leadership position in Mexico", said Franz Friedrich Butz, President of HA and Board Chairman.

Behind the HA name is more than fifty years of superior quality and service to the metal casting industry. Because the quality's in it-our name is on it.

HA-International is proud to be attending the 2019 College Industry Conference, November 21 & 22 in Chicago.

HA-International is proud to be attending the 2019 College Industry Conference, November 21 & 22 in Chicago.

Hope to see you there!

More info: Click Here

Reducing Shrinkage in Aluminum Castings With Resin Selection

As casting geometries become thinner in design and more complex, the influences from resin selection will place a more crucial role in providing a solid casting. An aluminum foundry was experiencing issues with a dendritic type shrinkage defect that was related to a recent change in a resin package, resulting in higher scrap rates from the shrink defect.

The only variable that changed and created the dendritic type shrink defect in this case was the resin. HA-International designed an experiment to determine how PUCB resin percentages, and solvent packages used in urethane cold boxes affected the influence of shrink on this particular aluminum A316 casting during solidification.

Evaluation occurred on a newly developmental phenolic urethane cold box and a modified version of this new system, utilizing the latest solvent packages found in HAI's SigmaCure series of phenolic urethane cold box (PUCB). The experimental setup of the study included computer aided modeling, analytical testing, and actual casting tests to generate cooling curves. These results, in conjunction with the temperature dependent properties were used to create simulation model datasets for the cold box sand mix in order to simulate the actual sand mold physical properties and understand how it was creating the shrinkage defects. Between 1,500-2,000 design iterations were conducted in modeling software to obtain a dataset that matched the results from actual lab casting results. The specific heat capacity and density results required for the simulation datasets were measured directly using instrumentation on test molds.

HA-International Announces New Business Development Director

WESTMONT, IL (September 2019) – HA-International announced today that Kelley Kerns has joined their leadership team as Director of New Business Development. Kerns comes to HAI with extensive technical and operations experience in the foundry industry.

"Kelley brings a strategic mindset and proven track record of developing new technical initiatives as he holds numerous patents in the foundry industry," said Michael Feehan, President. "We look forward to his contributions to building our business and brand."

Previously, Kerns was Director of Sales for the Foundry, Metals and Lime Group at Covia. Prior to that, Kerns was Senior Director of Operations at Fairmount Minerals where he held many technical service and management roles in his 20+ years with the company. Kerns began his career at Ashland Chemical working in the Foundry Products Division.

Kerns graduated from The Ohio State University with a master's degree in Business Administration and has additional degrees from the University of Northern Iowa. Recently, he was the 2018 President of the Foundry Education Foundation.

Enviroset 3D Jet Resins from HA: Robust 3D Printing Resins Producing Remarkable Results

HA-International has been supplying binder and activators specifically designed for 3D sand printing for over five (5) years, which means we have been developing superior furan resins, including those for all 3D printers for sand core and molds, for more than 20 years. Our low viscosity resin has been specially manufactured for use in all sand core and mold 3D printers, for use with all types of metals.

When it comes to experience with 3D printing of sand and mold cores, our reputation has stood the test of time.

MEASURABLE RESULTS

HA delivers superior print head compatibility and longevity with the dimensional accuracy 3DP casting customers demand. And, our unique combination of binder and select activators provide the fastest part extraction and ease of cleaning. And... our resins are priced more affordably than others on the market.

BENEFITS

- Increased productivity – resin helps print heads to last longer

- Reduced labor – printed molds and cores are cleaned faster

- Reduced costs – resin is very economical

HA Group Announces New Joint Venture in Mexico with Garmi to create HA Quimica de Mexico

Hüttenes-Albertus Chemische Werke GmbH (HA) and Garmi del Norte S.A. de C.V. (Garmi) announced their new joint venture, which will be serving the Mexican foundry industry. With this transaction HA Group will bundle all its commercial activities in Mexico in the new corporation named HA Quimica de Mexico S.A. de C.V. (HAMEX).

HA-International LLC (HAI, a HA Group company) is the market leading manufacturer and supplier of foundry resin systems, resin coated sand for shell molding and refractory coatings for North America. Garmi, a market leading manufacturer, distributor and supplier of foundry products and logistical services in Mexico, has been a longstanding representative of HAI in the northern region of Mexico.

"This new joint venture represents an important step for the HA Group, and further strengthens our foundry leadership position in Mexico", said Franz Friedrich Butz, President of HA. His Co-President Christoph Koch adds "The joint venture with Garmi demonstrates our long-term commitment as a solutions provider that is well positioned to deliver sustainable customer value within the foundry industry, while broadening our product portfolio and providing innovative technologies and services to our customers globally."

Optimized Feeding Systems

It is well known that metals change volume during solidification. This volume change must be compensated during solidification otherwise shrinkage defects can occur in a casting, making it unusable for its stated purpose.

This has been solved through the use of adding a metal reservoir commonly known as a "feeder" the purpose of which is to supply liquid metal to the casting as it cools and solidifies.

As this technology has developed and been improved, newer types of feeder materials have become available, including combinations of exothermic-insulating and highly exothermic compositions. The choice of material depends upon the application.

Thank You for Visiting HA-International at Cast Expo 2019

We know your time is valuable and trust that you were able to find everything you needed. Our new introductions of CHEMEX feeders, Enviroset® 3D Jet Resin & Catalyst, UCB Sigma Cure 138/238, EcoFlo Resin Coated Sand and EcoLite VOC Exempt Coating were met with great enthusiasm.

If we can assist with your Resin, Resin Coated Sands, Refractory Coatings, Feeding Systems, or Metal Treatment, please contact us.

Our overriding goal is to provide the technical expertise and products to help all foundries achieve higher productivity and profitability.

We also encourage you to "Follow HA-International" on LinkedIn for the latest in company news, research highlights and new products.

To follow HA, CLICK HERE.

Regards

Andy Koch, Vice President Sales & Marketing

HA-International

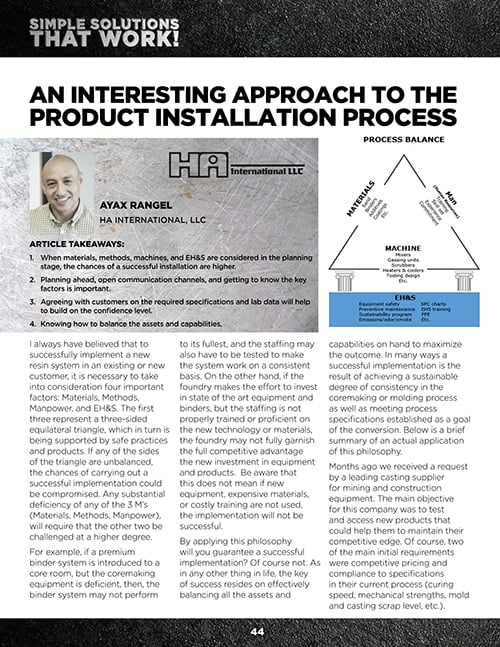

An Interesting Approach to the Product Installation Process

I always have believed that to successfully implement a new resin system in an existing or new customer, it is necessary to take into consideration four important factors: Materials, Methods, Manpower, and EH&S. The first three represent a three-sided equilateral triangle, which in turn is being supported by safe practices and products. If any of the sides of the triangle are unbalanced, the chances of carrying out a successful implementation could be compromised. Any substantial deficiency of any of the 3 M's (Materials, Methods, Manpower), will require that the other two be challenged at a higher degree.

EcoLite

EcoLite refractory coatings feature the latest light-off / fast drying technology. By using VOC-Exempt solvent packages, the flexibility and advantages of solvent based coatings can now be realized while minimizing the permitting of VOCs. Whether lowering the VOC impact of alcohol coatings or increasing productivity of water based coating applications, EcoLite coatings provide a unique value to today's foundry.

Environmental stewardship: NOT JUST A TREND

The metalcasting industry has a great reputation when it comes to recycling. However, environmental stewardship involves more than recycling. Using materials with more advanced environmental benefits is where metalcasters can take a leading role to mitigate some of the environmental challenges they face while creating a healthier and safer work environment.

Understanding 3D Sand Printers and Binder Technologies

AM for cores and molds is gaining popularity because of the flexibility and complexity it offers in production, but productivity is critical to the long-term prospects

Additive manufacturing of sand cores and molds has attracted the attention of many foundries in recent years due to the process' unique ability to form core shapes that cannot be manufactured using conventional coremaking techniques. It does this by a process called "binder jetting": a reactive resin, most commonly, a furfuryl alcohol-based (FA) binder formulated for the application is deposited on a substrate. Typically, the substrate is a silica sand that has been pretreated with an acid catalyst, but it can be a number of other aggregates used in metalcasting, such as zircon and synthetic ceramics.

HAI Feeder Technology - Powered by Chemex

Finally, casting feeder technology that produces a shrinkage free casting while decreasing production costs on even the most complex designs.

Patented Tele-feeder Systems are especially ideal for complex castings including intricate designs and rapid molding processes. This technology uniquely allows feeder placement in previously inaccessible locations.

Significant Benefits:

- Increases productivity with higher yield and faster cleaning time

- Increases quality with reduced casting scrap and rework

- Reduces environmental footprint with reduced energy

- Expands the locations for feeder placement

- Reduces surface defects with fluorine-free material

Wedron Flux Processing System - Announcements

- New drossing, clearing and degassing fluxes for copper based alloys. Eco grades reduce porosity by removing dissolved gasses in your copper based alloys. Simple plunge applications are very effective in reducing your scrap rate.

- Our new Zinc flux can be used on emersion tube melting and holding furnaces without corrosion concerns.

- HA-International has the only non-reactive commercial grade LEAD flux. Reduce the metallic content of your dross. Weight reduction saves not just alloy, it's an ergonomic savings. A reduction of up to 40% in weight will reduce operator injuries.

- Our Rotaflux and Injection systems have been upgraded and now have the ability to harvest data. Now you can find out what happened on third shift two weeks ago. Our systems record all functions or each cleaning and degassing cycle:

- Retained Data Options

- Operator Identification

- Ladle or Furnace Identification

- Time and Date

- Gas Flow Rates

- Flux Addition

- Rotor Speed

- Rotor Amp Draw Indicates Performance

- Cycle Times, Injection & Purge

Evolution of Foundry Shell Sand for Today's Foundry

Simple Solutions That Work - (Issue 9, September 2018)

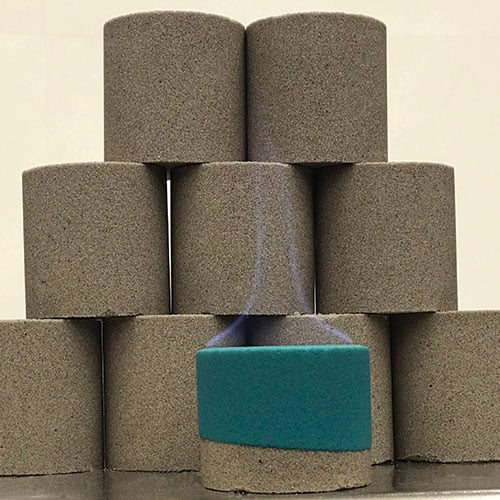

The Shell Sand process or "Croning" process was invented by Dr. Johannes Croning in Hamburg, Germany in 1944. This process is the oldest core and mold making technology that utilizes synthetic resins. Although many additional sand core and molding making technologies have since been introduced, the Shell Sand process is still a very effective core and molding process today.

Enviroset 3D Jet Resin

Enviroset 3D Jet Resin, is a low viscosity thermosetting furan resin that has been specially manufactured for use in all 3D Printers for sand cores and molds and is suitable for use with all types of metal. This furan resin offers a number of features and benefits that set it apart from conventional furan resins on the market — contains no nitrogen, low water, non-reportable formaldehyde and phenol, low viscosity and high tensile strength

ISO Certification

All of HA-International's primary manufacturing facilities have met the rigorous quality standards required for ISO 9001:2015 certification. International Organization for Standardization (ISO) 9001:2015 is the most updated standard of its kind and focuses on quality management systems and performance. It assists companies in developing a management system that aligns quality with their wider business strategy.

View our certificate here: ISO Certification

EcoFlo

CC EcoFlo is an environmentally friendly resin coated sand that is part of the HA-International EcoMission product line. CC EcoFlo is designed to both reduce ammonia and formaldehyde emissions while improving humidity resistance compared to other environmental grades. CC EcoFlo maintains strength in shell cores, emits minimal ammonia, and most importantly, reduces lumping propensity, even in hot and humid conditions.

Doug Trinowski Presents Hoyt Memorial Lecture

MILWAUKEE, Wisconsin - (April 2017) - The American Foundry Society’s Hoyt Memorial Lecture was established in 1938 and has been a highlight of every AFS Metal Casting Congress since then. The chosen lecturer is selected for his/her contributions to the metal casting industry and this year HA-International’s Douglas Trinowski was given the honor of presenting the lecture. His presentation was on “The Power and Need for Research in Metalcasting”. Doug gave an engaging presentation on past metalcasting research that has led to measurable improvements in the industry and focused on the need for continued research as supported by AFS. He also outlined many examples of critical needs and challenges in the industry that can only be resolved with organized research. Finally, Doug focused some time on how research is conducted in various countries and the need for improving the technical transfer process.

Doug is the former Vice President of Research and Development for HA-International and the current Director of Special Projects. We are a successful organization today due in large part to the leadership of Doug and the contributions of him and his team over many years.

Hüttenes-Albertus Announces Purchase of Hexion's Interest in HA-International, LLC

DüSSELDORF, Germany and COLUMBUS, Ohio, USA / - (June 1, 2016) - Hexion Inc. ("Hexion") and Hüttenes- Albertus Chemische Werke GmbH ("HA") today announced that Hexion has sold its 50% interest in HA-International, LLC ("HAI"), a joint venture serving the North American foundry industry, to its joint venture partner HA-USA, Inc., an entity controlled by HA.

HAI is the market leading manufacturer and supplier of foundry resin systems, resin coated sand for shell molding and refractory coatings for North America. HAI will continue a strategic sourcing arrangement with Hexion's Louisville, Kentucky site. Terms of the transaction were not disclosed.

Read more in our Press Release.

HAI Celebrates 15 Year Anniversary

While this is the 15th year since becoming HA-International, we celebrate a rich history that dates back over 80 years. This year marks 15 years since Delta-HA and Borden Chemical successfully merged to create HA-International. On their own, these two organizations enjoyed a rich history in supplying quality products and cutting edge technology to the North American foundry industry. For the past 15 years, HA-International has leveraged these past successes to become the leading supplier of resins, resin coated sand, refractory coatings and additional product lines that support the industry.

We recognize that the industry is facing new challenges which we believe will open the door for opportunity. HA-International�s philosophy, rooted in passion for performance, quality, consistency and customer focus, drives us to re-invent our products and services. This year we look forward to a pipeline of innovations, from updated product technology, to the recent launch of a customer facing app and modernized website. We are excited about what�s brewing at HAI and we look forward to another 15 years of sharing success with our customers.

.png?width=268&height=81&name=logo-new2%20(1).png)