Compact-Feeder

Compact -Feeders have an increased wall thickness compared to classic insert sleeves. The resulting increased exothermic reaction allows the inner fender to be reduced in volume, leading to improved output.

The good insulation properties of the Cold-Box-bonded formulations support this effect. This product range is part of the classic feeder systems and is suitable for molding onto the pattern plate and core shooting.

Benefits of Compact-Feeders

Compact-Feeders were developed as an alternative to classic feeder caps. Due to their more complex geometry, as well as the development of innovative bulk formulations, the Chemex Compact-Feeders offer a wide range of benefits for our customers:

-

Lower scrap rates

-

Lower melting costs

-

Fluorine-free formulations

-

Optimised outer geometries

-

Higher yields

-

Smaller footprints

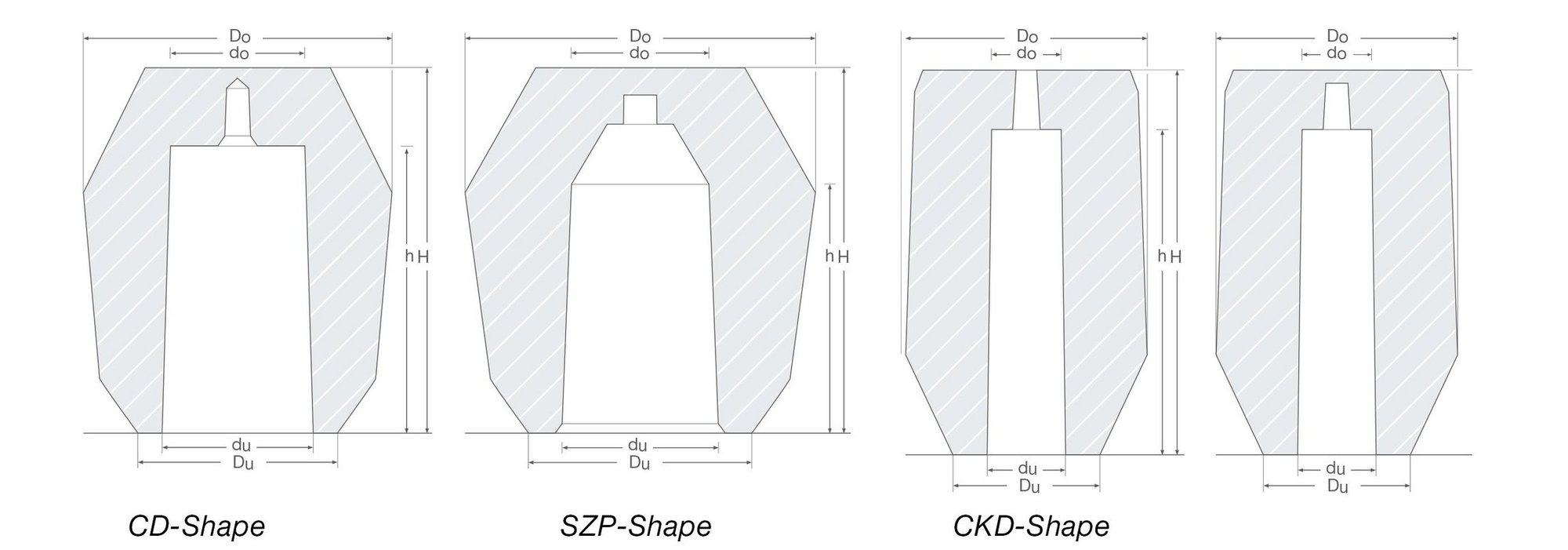

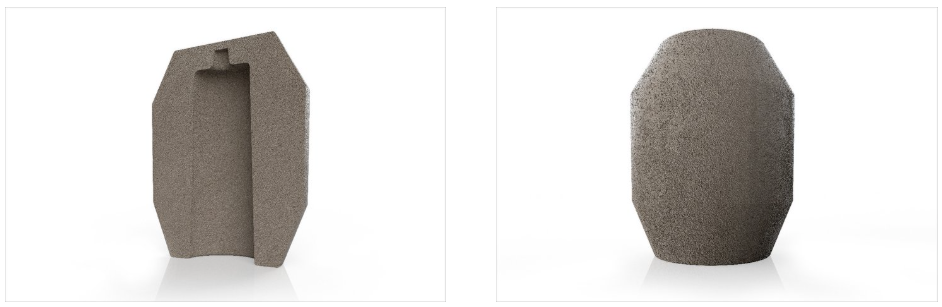

The CD-Shape

- More exothermic material and a more massive, complex outer geometry result in higher output

- Smaller contact zone

- Fluorine-free formulations prevent surface defects

The CKD-Shape

- Excellent output due to smaller internal volume and much higher volume of exothermic material

- Specially developed and optimised for small module areas

- Smaller footprint

- Fluorine-free formulations prevent surface defects

The SZP-Shape

-

Can be configured as the upper part for the Tele-Feeder thanks to the self-centring inner geometry

-

Increased feeding volume thanks to more voluminous internal geometry

-

Available with W-bar

-

Available with an oval diffuser

-

Fluorine-free formulations

Discover our EK TYpes

.png?width=350&height=350&name=Untitled%20design%20(37).png)

Your contact

Brodie Biersner

Senior Product Manager Feeders

.png?width=268&height=81&name=logo-new2%20(1).png)