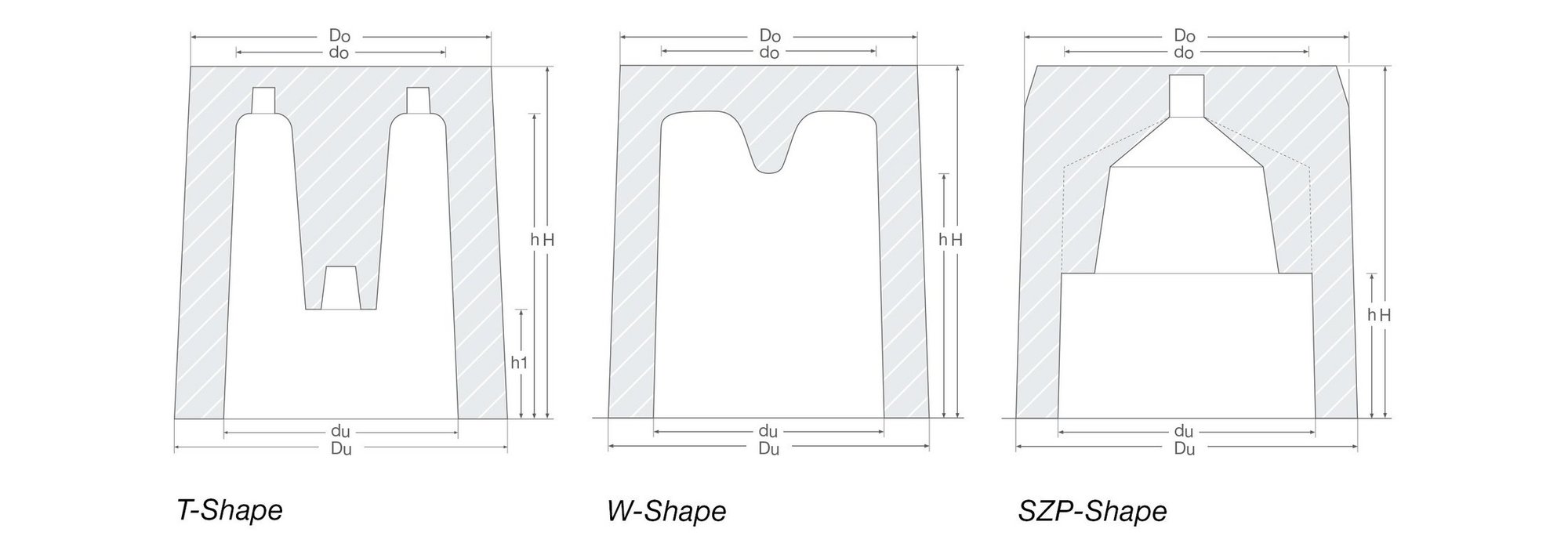

EK Types

EK Types are the oldest form of feeder inserts and were originally designed for subsequent insertion into the turned upper box (cope). If required, they can also be fitted with a breaker core.

Today, these sleeves have very high strengths, so they can easily be moulded onto the pattern plate or shot into cores. Chemex has further developed these classic feeder inserts with the T-Types. This variant of the insert sleeves has a smaller internal volume for the same module than the classic insert sleeve.

The yield can be significantly increased by using this variant.

Benefits of EK Type

EK Types are the oldest form of feeder systems. Thanks to our years of experience and the constant development of innovative formulations and geometries, our EK Types offer a wide range of benefits for our customers:

-

Lower melting costs

-

Lower scrap rates

-

Fluorine-free recipes

-

Proven feeding technology

-

Easy application

-

Low costs

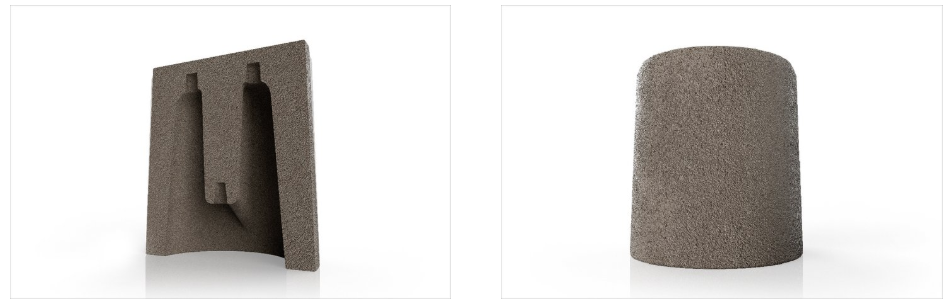

The EK T-Type

-

Reduced height and diameter with the same module compared to the classic W Shape

-

Less recirculated material thanks to the smaller internal volume and higher output than the classic W Shape

-

Fluorine-free formulations prevent surface defects

The EK W-Type

-

W-bar prevents edge shell formation and guarantees optimal feeding

-

Less exothermic material thanks to the cylindrical outer geometry

-

Fluorine-free formulations prevent surface defects

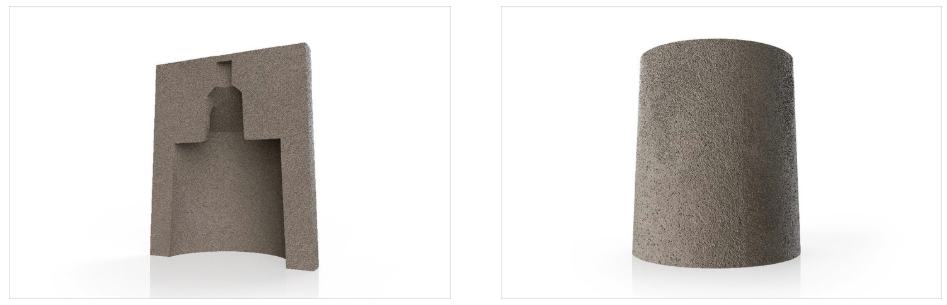

The EK SZP-Type

- Can be configured as the upper part for the Tele-Feeder thanks to the self-centring inner geometry

-

Easy to place on the pattern plate

-

Available with W-bar

-

Increased feeding volume thanks to more voluminous internal geometry

-

Fluorine-free formulations

Our Telescopic Technology is also available for vertical molding lines

.png?width=350&height=350&name=Untitled%20design%20(37).png)

Your contact

Brodie Biersner

Senior Product Manager Feeders

.png?width=268&height=81&name=logo-new2%20(1).png)