HPDC Die and Shot Tip Lubricants

HAI's product range includes Die and Shot Tip Lubricants for High Pressure Die Casting (HPDC)

Die casting solutions

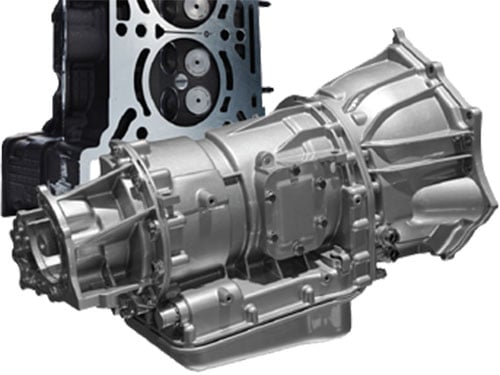

Die casting is a high-precision and highly productive casting process that has experienced something of a revival in recent years caused by the growing demand for weight reduction in the automotive industry. In order to produce ever larger structural and body parts, casters have invested in larger die-casting machines with locking forces of 3,500 tons and above.

Die casting is a high-precision and highly productive casting process that has experienced something of a revival in recent years caused by the growing demand for weight reduction in the automotive industry. In order to produce ever larger structural and body parts, casters have invested in larger die-casting machines with locking forces of 3,500 tons and above.

HAI's product range includes the consumables casters need for this highly automated casting process, which is still relatively new compared to classic casting processes.

Die Lubricants

Before each shot in the die-casting process, a release agent is sprayed onto the surface of the cavity to achieve a range of functions and properties:

- Separating the aluminum or magnesium alloy from the steel die and avoiding sticking/welding by preventing the formation of an intermetallic phase like FeAl3

- Creating the lubricating effect required to eject the casting and to lubricate moving parts, such as slides and ejector pins

- Making it easier to fill the dies

- Providing additional die cooling during spraying

Given the extremely diverse range of parts, which includes everything from solid, thick-walled parts such as cylinder crankcases to very thin-walled, flat parts such as shock towers and A-pillars, die lubricants face many challenges.

This is why HAI’s product portfolio includes release agents with a variety of compositions to ensure that we can provide the right solution for every single application.

There are two fundamentally different application types to lubricate the die:

HAI Trennstoff is applied undiluted by the spray method. The best release effect is achieved as a thin film with short spraying times. With appropriate spraying equipment, the product can also be used in micro spraying.

Application of wax-based pellets in the shot tube or cold chamber

HAI Trennsol is dosed with the HAI Trennsol TV unit, which converts the pelletized release agent into the gaseous state and vaporizes on the die surface with dry pressurized air. Due to the temperature difference between the die cavity and the gaseous release agent, the latter condensates on the die cavity surface, forming a uniform lubricating film.

Shot Tip (Piston) Lubricants

There are two fundamentally different application types to lubricate the shot tips:

HAI’s high-performance oil can be used universally for many piston/casting chamber pairings and casting alloys. Due to its composition, the product does not interfere with the post-treatment of castings.

Application of wax-based pellets in the casting chamber in front of the tip head

The surface temperature of the casting chamber (min. 180°C/356°F) makes the pellets melt, and the liquid-state lubricant is drawn into the gap between the piston and the casting chamber via capillary action. The main advantage of this lubrication method is a much cleaner environment around the casting chamber.

HAI offers different pellet types for specific challenges, all of which are free of graphite, which sooner or later would otherwise end up coating everything with a dark grey, greasy layer. As an alternative to graphite, the HAI pellet type with the highest lubricating performance uses an extremely effective alternative raw material, which allows it to be used for piston diameters of up to 160mm.

In order to ensure optimal use, HAI also offers its customers the Pellet Feeder and Mobile Pellet Feeder dosing units. These doses the specified amount of pellets into the casting chamber without allowing any pellets to bounce back out. As a result, casters benefit from a much cleaner environment and an efficient, loss-free pellet dosing process.

For additional product information, contact Bryan Dahms, Application Specialist at 937-622-5848 or bryan.dahms@ha-group.com

.png?width=268&height=81&name=logo-new2%20(1).png)