Innovations

PRODUCTS

Bioset® opTa80/85

A cost-effective update to Bioset products. Less smoke and odor with more value.

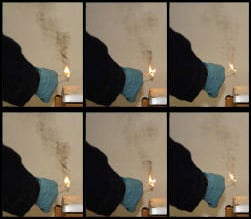

HA International's new, second generation of the Bioset T family of products is here! The Bioset opTa80 and Bioset opTa85 resin package will continue to move both HAI and the foundry market towards a greener future.

The Bioset opTa80/85 package was designed to have similar smoke and odor reductions as compared to the original Bioset T system with a great economic value.

HA International's new, second generation of the Bioset T family of products is here! The Bioset opTa80 and Bioset opTa85 resin package will continue to move both HAI and the foundry market towards a greener future.

The Bioset opTa80/85 package was designed to have similar smoke and odor reductions as compared to the original Bioset T system with a great economic value.

Bioset opTa80/85 is a revolutionary reformulation of our current formula, and still provides similar tensile and hot strength compared to Bioset T8000/T8500.

The benefits of Bioset opTa80/85

The benefits of Bioset opTa80/85

- Lower odor, smoke, VOC and HAP emissions at pouring, cooling, and shakeout (compared to standard PUNB)

- Superior tensile strength

- Low free formaldehyde

- High hot strength for ferrous and non-ferrous applications

- Comparable to the original Bioset®T system

FACILITIES

HA-International Announces Further Investment in Chemex Feeder Manufacturing — Toledo, OH

HA-International continues to invest in business development, most recently in domestic manufacturing capabilities at their Toledo, OH facility to support the Chemex Foundry Solutions. The investment in the Toledo facility which has 65,000 sq-ft under roof and 10 acres to expand added infrastructure, coldbox sleeve production with assembly to meet the rapidly increasing demand from North American customers for Chemex Telefeeder Technology. Production was brought online 1st quarter 2021 with the continuation of future investment of $2.5 million in production tooling over the next few years directly affecting supply chain management to intensify capabilities and capacities. The next strategic focus is domestic sourcing of the raw materials and manufacturing of sleeves dry mix to support the expected volume growth. These efforts are to streamline the impact of leadtimes and logistics while providing innovation and value for each customer.

Chemex Foundry Solutions was founded in 1974 in Germany and is a subsidiary of the HA Group with manufacturing locations in Toledo, Ohio, Delligsen, Germany and Istanbul, Turkey. Chemex is a global leader in the field of feeder technology. Nevertheless, the company never rests on its laurels or stops researching and developing new products: As members of the HA Group, HA-International, LLC and Chemex have access to the extensive expertise of one of the world's leading foundry technology suppliers. Offering customers ever better solutions, the company's research and development team is constantly working on and testing new materials and approving them for hand-molding and series production of ferrous and non-ferrous castings.

Chemex feeder systems are especially engineered for challenging castings including intricate designs and molding processes. The exceptional variety of our products assures our customers an optimal selection of feeding systems. The ultramodern method of fabrication with cold box binder systems combined with the innovative Telefeeder technique represents a state of the art in the area of feeder technology. This technology uniquely allows feeder placement in previously inaccessible locations.

For more information on HA-International and Chemex Feeding Systems, please contact feeders@ha-international.com or call +1.630.575.5700.

Chemex feeder systems are especially engineered for challenging castings including intricate designs and molding processes. The exceptional variety of our products assures our customers an optimal selection of feeding systems. The ultramodern method of fabrication with cold box binder systems combined with the innovative Telefeeder technique represents a state of the art in the area of feeder technology. This technology uniquely allows feeder placement in previously inaccessible locations.

For more information on HA-International and Chemex Feeding Systems, please contact feeders@ha-international.com or call +1.630.575.5700.

PRODUCTS

CastTherm® Chromite

CastTherm CR Chromite provides excellent chill properties for castings with heavy metal sections as well as castings with intricate details.

Features:

- 3 grades – 45, 60, and 80 GFN available to meet the demands of iron and steel foundries

- Packaged at the manufacturer to reduce dust during transport improving turbidity and tendency for segregation improving overall quality

- Highest chilling properties as a result of high Cr2O3 percentage and less than 1% SiO2 content

- Low turbidity

- High melting point

Benefits:

- Lower cost in use versus zircon

- Highest chilling properties of any molding media for thicker solidified skin

- Excellent thermal conductivity for castings with heavy sections for better surface finish

- Reduced cleaning time and improved surface finish in comparison to other sand, additives, and coating applications

PRODUCTS

CastTherm® CE Ceramic

CastTherm CE H Series ceramic media is produced with a unique combination of chemical, physical and thermal properties that provide performance advantages. CastTherm CE H Series is engineered for high pouring temperatures and long-term heat duration with making very large steel and iron castings while minimizing defects.

Features:

- High refractoriness

- Low linear thermal expansion

- Tough, durable in performance – Uniform and spherical in size and shape

- Chemically inert and non-hazardous, contains no crystalline silica

Benefits:

- Maximize tensile with less resin

- Withstands high temperature pours of various metal castings

- Increases dimensional precision and ability to pour complex parts

- Reduces expansion-related defects

- Reduces casting cleaning times

- Increases production, reduces particle breakdown, and supports recycle use

- High permeability, lower resin - reduces gas-related defects and associated costs

- Improved quality, health, safety, and sustainability

AWARDS

Ecovadis

Minimizing our impact on the environment is part of HAI's EcoMission. Our goal is to minimize foundry environmental impact throughout our product's life cycles, with an ongoing commitment to continuous improvement. View our EcoMission video.

To be recognized as an EcoMission classification, each of our products must meet at least three out of five environmental criteria:

- Utilizes water or renewable components

- Utilizes recycled components

- Low Volatile Organic Compound (VOC)

- Low Hazardous Air Pollutant (HAP)

- Low Odor

.png?width=268&height=81&name=logo-new2%20(1).png)