Chem Bond

Inorganic Binder Sands

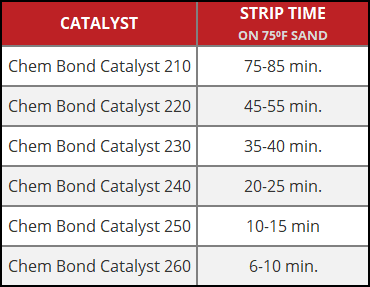

Chem Bond No-Bake binder systems have several advantages compared to furan or oil No-Bake binders. They are primarily inorganic; this results in very low gas and smoke emission in the foundry. The Chem Bond binders differ from competitive No-Bake sodium silicates in that working life and strip times can be adjusted without affecting the through cure of the sand mass. Neither binders nor catalysts are toxic. There is no need for special packaging. Chem Bond bonded sands possess good flowability and a high ratio of working life to strip time.

Chem Bond No-Bake sands can be used in the foundry to replace normal green sand molding operations and other No-Bake binders. They provide improved casting dimensional control and casting finish. Also, casting defects caused by gas, as well as expansion defects, can be reduced or eliminated.

Compared to other No-Bake systems, these products offer a significant improvement in the foundry environment. Smoke, odor, and fume emissions from the Chem Bond processes are either absent or at very low levels.

Chem Bond 5210 is a silicate binder that can be cured with a CO2 gas Cold-Box or a liquid catalyst No-Bake process.

For additional product information, contact Aaron Kaboff at Aaron.kaboff@ha-group.com.

.png?width=268&height=81&name=logo-new2%20(1).png)